A port planner knows that the efficiency of a terminal could already be decided during early port planning stages – just by looking at predicted vessel motions. There’s a way to do so even more efficiently as I will describe below. In the initial planning process, all kinds of dynamic impacts should be included into the picture.

Dynamic impacts to be considered during port planning. © DHI

Here are three steps to ensure optimal port efficiency:

-

-

- Consider the boundary conditions

A port planner needs to take into account many boundary conditions, such as space for the pier operator for cargo handling, transport, facilities, as well as space needed by the vessels for bypassing and turning, and so on.Think about environmental aspects, for example, by aiming for a calm harbour basin. Think about breakwaters. Try to reduce currents and if possible, have the quay lying in such a direction that the wind will often push the moored vessel into the fenders. These considerations will reduce vessel motions. Smaller vessel motions mean higher terminal efficiency.

- Apply extreme value analyses and numerical modelling

Predictions for wind conditions and all kinds of waves and currents in a port can be made by using long-term measurements and numerical modelling, which affect berthing conditions. For example, long period waves (swell, long fetch lengths, passing vessels) can reduce the operability of terminals. Combined with extreme value analyses, a port planner would know how often each condition is likely to occur. - Conduct dynamic mooring analyses

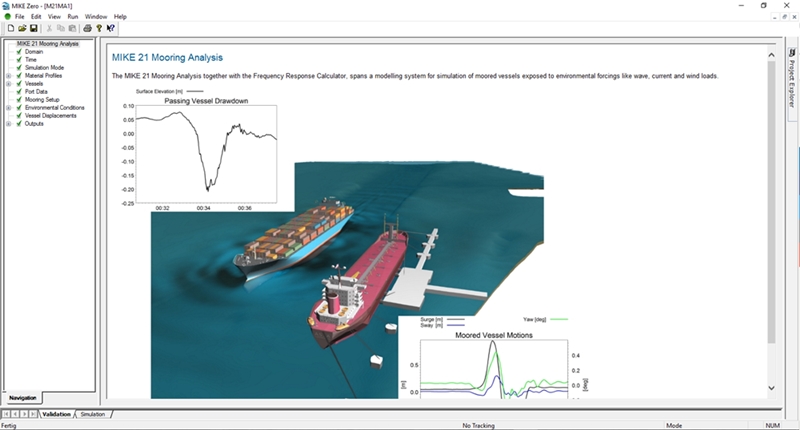

The data above should be used directly in dynamic mooring analyses, which provides vessel motions, line and fender forces. With such a tool, meteorological and hydrodynamic data in a test matrix can be combined freely. The impact of passing vessels can be incorporated, and one takes into account that waves and currents can be very different over the entire vessel length.

- Consider the boundary conditions

-

So how can mooring analysis be done even more quickly and accurately?

The answer lies in an extremely quick tool that allows the testing of an entire matrix in a batch, enabling exceptionally precise insight into vessel motions that need to be expected in the port design. This tool helps in predicting port downtimes and has the ability to test different considerable designs. Test how efficiently a port can be optimised by selecting the design that gives the lowest downtimes. One can imagine how quickly a few percent will pay off already.

The dynamic mooring analysis software features a straightforward and user-friendly interface that anyone can learn to use. © DHI