The Danish government’s Climate Plan for a Green Waste Sector and Circular Economy sets ambitious goals to make the water sector climate and energy-neutral by 2030. Achieving these targets requires not only improving existing processes but also implementing innovative technological solutions to enhance sustainability. Among these, digital twins represent a promising opportunity, enabling the safe and efficient testing and implementation of optimisation strategies without disrupting daily operations.

In Denmark, wastewater treatment plays a vital role in environmental protection but is also a significant source of greenhouse gas emissions within the water sector. Nitrous oxide (N₂O) is particularly impactful, with a global warming potential 273 times greater than that of carbon dioxide (CO₂). Emissions of N₂O from treatment plants account for 57% of the sector’s direct greenhouse gas emissions, equating to approximately 67,000 tonnes of CO₂ equivalents annually. Addressing N₂O emissions is therefore essential to achieving national climate targets and contributing meaningfully to the green transition.

Challenges and technological opportunities

Reducing emissions while maintaining high effluent quality and operational efficiency poses a considerable challenge. One emerging solution is the use of digital twins – an advanced digital approach that integrates real-time data with process models to simulate and optimise plant operations. Although digital twins are already utilised in various industries, their application in wastewater treatment, particularly for targeting N₂O emissions, is still relatively novel.

A digital twin incorporating N₂O processes provides a comprehensive overview of how different operational strategies influence emissions. Acting as a virtual replica of the treatment plant, it allows simulation of changes in aeration strategies, carbon dosing, and sludge management. By predicting emissions in real time and assessing scenarios, plant operators can identify and implement the most effective solutions for reducing climate impact.

N₂O emissions primarily arise during biological treatment processes where ammonium is converted into nitrate and nitrogen gas. High ammonium loads, oxygen concentration fluctuations and operational stress can exacerbate N₂O formation. Reducing these emissions demands a thorough understanding of the underlying processes and their integration into the plant’s broader operational strategy – precisely the capabilities offered by digital twins.

How does a digital twin work?

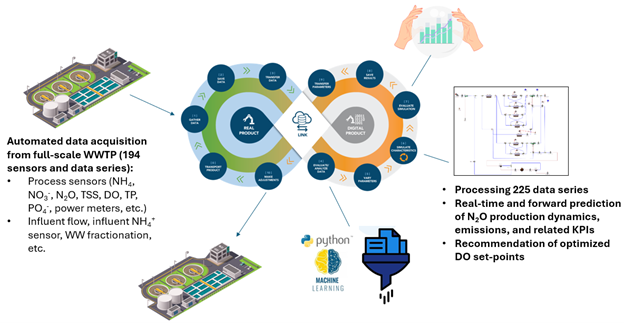

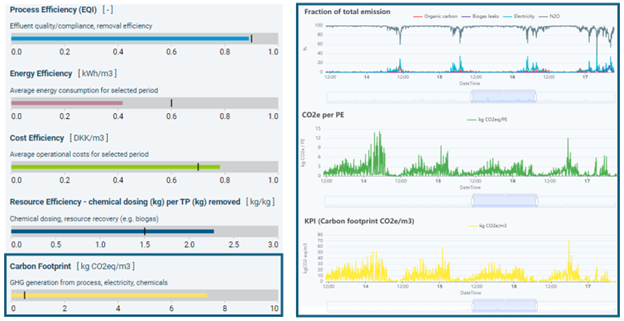

A digital twin integrates sensor data, process models and advanced software to create a dynamic representation of a treatment plant. This technology enables utility providers to simulate and predict plant performance under varying operational conditions. Scenario-based evaluations reveal how changes in load, temperature or other factors affect N₂O emissions and key performance indicators (KPIs) such as operational costs, climate impact and resource efficiency.

Scenarios can be configured to explore optimisation potentials for key performance indicators such as energy balances, CO₂ footprints and treatment efficiency. Control settings can be transferred from the twin to the physical plant and their effects verified in the real system.

Digital twins combine the following components:

- Real-time data collection: Continuous data from sensors provides an updated picture of the plant and serves as input for the model, undergoing quality control and processing.

- Simulation and forecasting: Mechanistic and data-driven models offer real-time insights and 48-hour forecasts of plant processes.

- User interfaces and dashboards: Visualisation tools display data and evaluate alternative operational strategies.

- Scenario configuration and evaluation: Operational parameters and input time series can be adjusted, enabling analysis of impacts on KPIs like energy balances, CO₂ footprints, and effluent quality.

Implementation in Denmark

An example of digital twin implementation is the Bjergmarken treatment plant in the Danish city Roskilde, which treats wastewater equivalent to a population of 125,000. As part of the TwiN2Ops research project, a digital twin was developed to model and calibrate N₂O-generating processes. It included energy balances, dynamic CO₂ footprint calculations and an inflow generator for predicting flow and concentrations based on rainfall data and catchment characteristics.

The model incorporated Hubgrade® aeration and phase control logic for precise plant descriptions. Results demonstrated a potential N₂O emission reduction of up to 30% alongside energy savings of up to 25%, without compromising effluent quality. The digital twin allowed the Bjergmarken plant to simulate strategies such as adjusting oxygen levels, implementing buffer capacity and modifying carbon input, identifying the most effective solutions for emission reduction while ensuring stable operations.

The path forward

Making wastewater treatment more sustainable requires leveraging available technological advancements. Digital twins offer an accessible method to understand and optimise the complex processes of treatment plants while balancing operational objectives such as greenhouse gas emissions, energy efficiency, operational costs and effluent quality. By combining real-time data, process models and strategic planning, the water sector can become greener and more efficient.

Prioritising investments in solutions that reduce emissions and enhance efficiency is crucial for meeting climate targets. Digital twins can help utility providers quickly and effectively pinpoint the most cost-efficient measures, ensuring resources are allocated where they make the greatest impact and accelerating the green transition. With this technology, Denmark has the potential to lead the way in sustainable wastewater treatment and contribute significantly to the global fight against climate change.

(This article was originally published in Danish in the industry media WaterTech on 13 December 2024)