This article first appeared The Water Digest.

Digital twins started to gain traction in 2014, and it is a buzzword nowadays. Many people are using the term ‘digital twin’, and many are still confused by it. What is a digital twin? What can it do? Is what I am doing a digital twin?

DHI and many partners in the Smart Water Network Forum (SWAN) digital twin workgroup started to band together a few years ago to address this. We see the potential and opportunities to gain from using digital twins in the water sector, but we also see many obstacles. One of these obstacles is aligning and getting a common understanding or language around digital twins. A common understanding will enable the water industry to move in the same direction. Technology providers can position themselves where they provide the best value, and utilities can better choose which technology fits their facility best.

‘Within utilities, cross-departmental collaborations must have a consistent view of a digital twin. The digital twin is a whole of many parts constantly in flux, and the water sector must agree on the fundamental concepts of what a digital twin is. Without this agreement, digital twins can lead to confusion and make it difficult to attain the desired outcomes they deliver.’

Extract from the SWAN digital twin readiness guide

What is a digital twin?

So, what is a digital twin? There’s no perfect definition, but our view is that a digital twin is a dynamic digital representation of real-world entities and their behaviours using models with static and dynamic data that enable insights and interactions to drive actionable and improved outcomes. The keywords are dynamic, allowing the interactions to drive actionable outcomes.

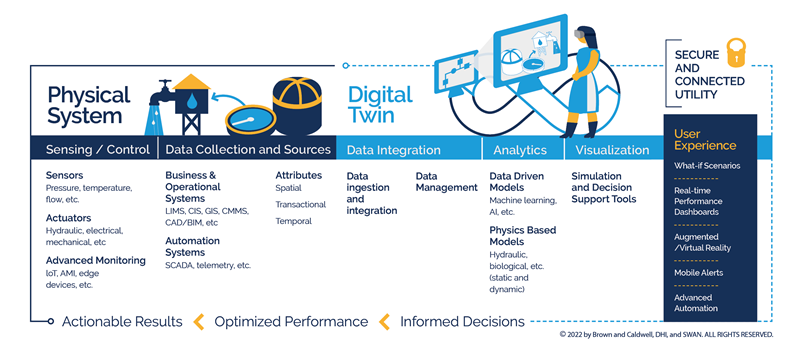

Digital twins consist of many different components, and the SWAN Digital Twin Architecture diagram gives a framework for categorising a digital twin’s main elements. This architecture framework can function as a checklist and lets you see the components and gaps you have to complete your digital twin.

The primary use of a digital twin is to improve decision-making. In general, decision-making comes in three categories – strategic decisions, which are long-term goals, tactical decisions, which are shorter-term steps that support the strategic goals and operational decisions, which are the day-to-day decisions. The digital twin that needs to support these decisions will be different in terms of how frequently it should update and how detailed it should be. For example, if you want to decide which infrastructural investments to make in your utility for the next five years, you don’t need a live update of sensor data and events. You need aggregated information of which are the critical areas in your infrastructure. However, if you want to make operational decisions like whether to turn off and on a pump and for how long, you want all the live and forecast data you can get your hands on, and you might even want to know what the possible consequences are. These decisions require different dynamic data and different granularity of the digital twin.

How do I evaluate my digital twin?

We believe that digital twins can be constantly improved on and expanded on, so starting a digital twin project is embarking on a journey towards better and more sophisticated digital twins. So how do you get to plan, design and implement your digital twin? We identified four main pillars of a digital twin that can help guide your way to evaluate your digital twin and how to proceed further. These pillars are – Outcomes, Technology and Connectivity, Insights, and Interactions and Actions.

‘These pillars form a foundation that grows as each utility progresses with the Digital Twin journey. Each pillar has its maturity level and can either positively or negatively impact the other pillars in achieving the desired outcomes. The pillar with the least maturity can be a future focal point in advancing a utility’s Digital Twin journey.’

SWAN digital twin readiness guide

The outcomes pillar are goals that drive the direction of a digital twin. Some examples are improved regulatory compliance, lower-cost operations, and a more reliable and resilient system. These outcomes should be as quantifiable as possible so that they can be used to track digital twins’ performance and plan further development.

Technology and Connectivity measure and track how much infrastructural assets are securely integrated, digitally sensed and controlled, and determine the limitation of how much influence and impact a digital twin will have. For example, a utility with high connectivity and high technology will be able to provide a digital twin with more real-time data, making the digital twin more reflective of the actual operational conditions. It will also enable a digital twin to provide more intelligent decision support and advanced automation.

Insights are a measure of information produced by models in the digital twin. They can be generated by analysis of simulations from data-driven or artificial intelligence (AI), physics-based models, or a combination of them. Insights give you an idea of what is happening, what has happened and what will happen in your system. Some analysis examples are anomaly detection, what-if scenarios, predictive operational parameters, etc. Typically, physics-based models (e.g., hydraulics models) excel in simulating expected design operating conditions in a utility, while a data-driven model simulates patterns in actual operating conditions. By combining real-time data in both physics- and data-based models, synergies are created that help generate more accurate and deducible insights for faster and better decision-making.

Interactions and Actions are the decision-support actions that the digital twin supports. Depending on who the digital twin is designed for, these actions can be for staff, including operators, engineers and managers. This support can be suggested setpoints or suggested work orders to create. In the more advanced scenario, Digital Twins can supplement programmable logic controllers (PLC) and provide intelligent control automation or a co-pilot to the operations team. This operational co-pilot enables operators to control devices like pumps and valves more dynamically and in more discrete time steps under their direct supervision.

How do I get started with digital twins?

We understand that there’s an architecture diagram that helps us know what a digital twin and the component of a digital twin is. We know that the four digital twin pillars can help us evaluate how mature and complete our digital twin is. Now, how do we get started?

While different utilities may have different levels of digital maturity in technology and company culture, the approach to implementing digital twins is common. The differences are the actions taken in each of these steps.

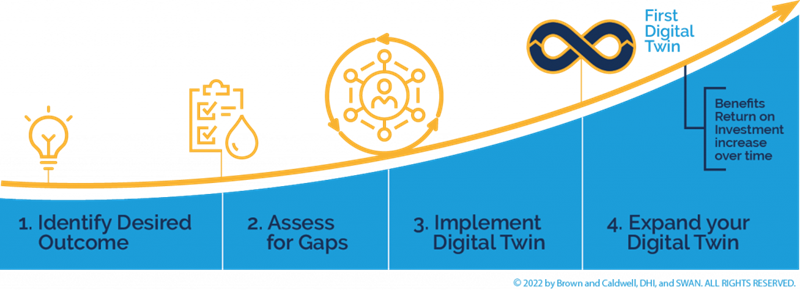

The digital twin journey is a four-step approach to guide utilities and anyone to plan, design and implement digital twins.

The first step is Identify – decide what you want to achieve. This can be a large system-wide goal or a specific sub-system goal. We recommend starting small, looking for low-hanging fruits, and making the goal as actionable as possible. This will be the guiding star of the direction of the digital twin.

The second step is Assess – what you have in your utility. We recommend using the architecture diagram to get an inventory of technology, initiatives and projects that can help you achieve the goal you have identified because it provides a framework that covers a high-level overview of the different components of a digital twin.

The third step is to Implement – an iterative approach and involve different stakeholders. Set some success criteria and make that communication clear for all stakeholders to understand the goal and metrics to measure. Review the metrics and iterate the implementation. You may have to change something because certain assumptions were wrong.

Finally, use the digital twin and continuously expand and improve on it. You can go back to the ‘Identify’ step and work on a new goal, so your digital twin gets more and more functionality over time.

We tested and derived this approach in over ten case studies to see how well they work. These case studies come from different parts of the world, from Europe to Asia and the US. They also cover all water value chains from water distribution to collection systems and wastewater treatment plants. So we believe this approach will work for all digital twins in the water sector.

Let us briefly go into one of the case studies and see how the digital twin journey is used, saving 30% of costs.

Gruppo CAP manages the integrated water services in the Milan Metropolitan area in Italy. In this case, we are looking at a wastewater treatment plant that serves around 250,000 population in Bresso municipality.

The first step is – Identify. They aim to optimise their facility by lowering chemical use and improving biogas production and biomethane separation operations.

The second step is – Assess. They assessed what they have and the gaps they need and identified that they needed more models, decision support tools, etc., using the SWAN architecture diagram. From that assessment, they engaged DHI to help them build the digital twin.

The third step is – Implement an iterative approach. Along the way, the team identified issues, such as data gaps from SCADA, connectivity between different IT systems, and the complexity of some processes, such as aeration control. However, they kept a clear goal and target and worked towards it.

The fourth step – use and expand. After the implementation, they used the digital twin to evaluate which control strategies work best and implemented the best strategy, saving them up to 30% of costs. Now that they have some success, they plan to include even more processes to optimise other control strategies.

I hope this gives you an idea of how the digital twin architecture, the pillars of the digital twin and the digital twin journey approach can be used to help you navigate your plans to implement your digital twin.