[This is the first of two articles we’re sharing on useful tools for each phase of offshore wind energy development. Take a look at blog two introducing specific tools for solving environmental challenges here.]

The global offshore wind industry is ever evolving as it matures in Europe, and swiftly progresses in Asia and North America. Offshore wind turbines will soon be 10 times bigger, many will be floating, and some will be built adjacent to artificial energy islands. The present and future engineering challenges for the global offshore wind industry are many:

- How to secure the best location to produce the most power?

- How to make more informed and strategic development decisions?

- How to ease development approval processes?

- How to reduce uncertainty and investment risks?

- How to ensure foundations remain sturdy despite attacks from waves and winds?

- How to improve safety and operational efficiencies?

- How to repower or decommission a project efficiently and sustainably?

Answering these questions and more requires precise understanding of site-specific conditions made possible with reliable data and tools.

The data and tools presented below can help developers and operators, both alone and in collaboration with experts, analyse marine environments for each development phase. For this blog, we broadly describe offshore wind farm phases as: (1) Strategic site selection, (2) Planning and development, (3) Installation and construction, (4) Operations and maintenance, and (5) Decommissioning.

Phase 1: Site selection

Assessing and selecting a project site requires verifying if it (1) produces enough wind to be financially viable, and (2) is environmentally feasible.

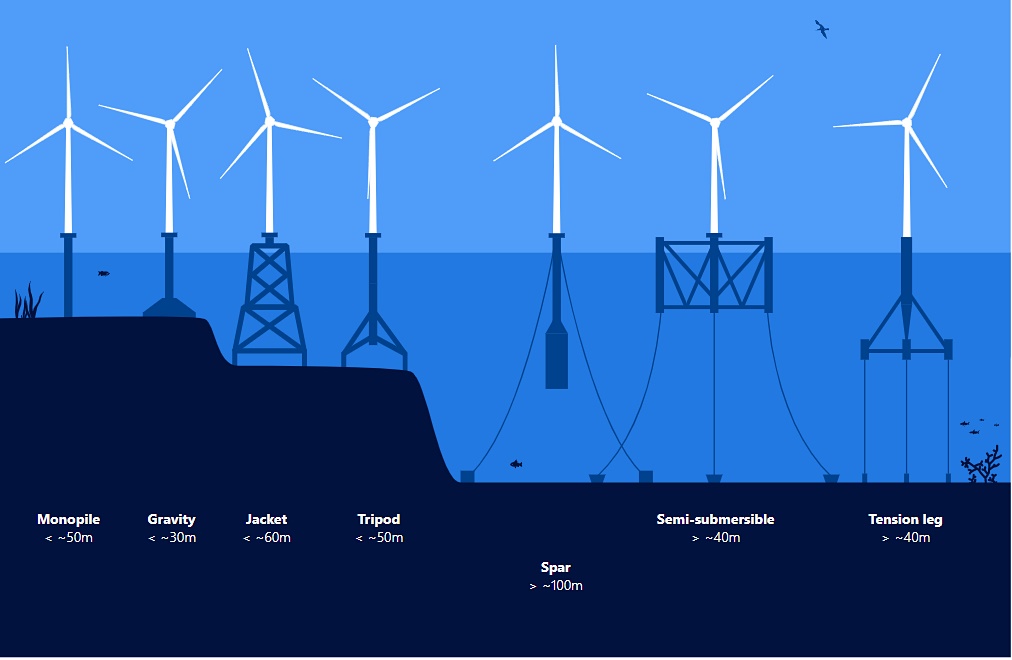

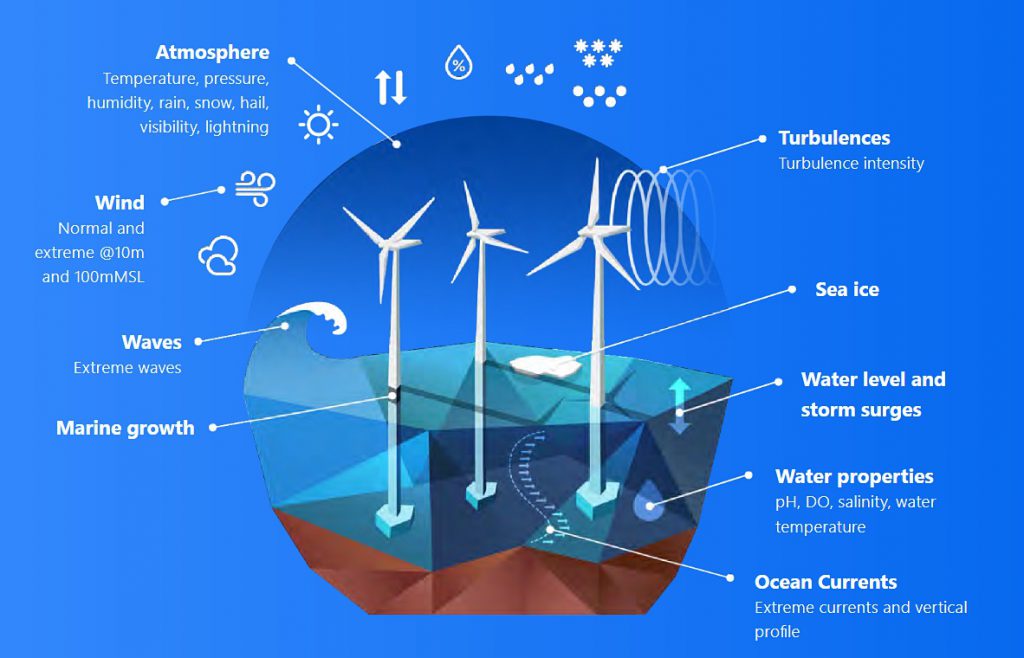

To verify the first, and complete other site selection tasks, accurate data and analysis of site-specific metocean factors – comprising weather (meteorology) and sea (oceanography) conditions – are needed. To ensure structural integrity and safe operations, it’s vital to adopt systems that match a site’s metocean conditions.

Various modules in the MIKE 21/3 modelling suite are used to assess both the engineering and environmental challenges.

In addition, tools like MIKE 3 Wave FM simulate extreme wave kinematics for evaluating impact loads and structure responses, and model seabed behaviour near foundation structures. The MetOcean Data Portal can help select and assess site-specific metocean and load conditions, map sea state condition data, determine site workability and design criteria for potential offshore installations.

The best part? Investing in and establishing area-specific data and models in the earliest possible phases means you can more easily adjust them for customised analyses in subsequent phases to save time and money.

Phase 2: Planning & development

In this phase, developers must complete plans and engineering design, secure planning consents and de-risk critical development decisions. To establish sound design criteria for the often-harsh environmental conditions, it’s best to deploy numerical models coupled with site-specific metocean data.

The MetOcean Data Portal uses numerical models and statistical methods to predict the effects of complex physical phenomena (like cyclones, typhons, etc.) on offshore designs.

Analyse loads and responses of structures in relation to environmental conditions using tools like MIKE 21/3 and Computational Fluid Dynamics (CFD).

Protect assets, analyse scour and seabed mobility, and compare mitigation options with the DHI Scour Calculator, Computational Fluid Dynamics (CFD) and physical model testing.

MIKE 21/3 can help model and evaluate seabed stability, including general seabed levels and impacts of migrating bed forms of offshore wind structures.

Phase 3: Installation and construction

Construction can’t take place unless meteorological and oceanic conditions are suitable. If operating tasks are poorly matched to the operating environment, certain tasks may suffer significant delays. To prevent delays and save costs, effective forecasting tools, like Metocean Risk Ops, can help.

Installation and construction strategies should include smart vessel planning to ensure safe personnel transfer. Recording vessel movements, metocean conditions and turbines during operations can also provide valuable information in the subsequent development phases.

Phase 4: Operations and maintenance

Operations and maintenance (O&M) tasks are typically managed locally, 24-hours a day. This is because the O&M phase is particularly sensitive, as tasks involving personnel transfer onto offshore structures requires suitable weather conditions for vessels and access systems.

Metocean Risk Ops helps collect and analyse metocean data to apply to an O&M strategy to ensure the highest levels of safety and efficiency during O&M tasks. Such a robust data and modelling tool can help develop and maintain an O&M strategy to:

- Plan, prevent and react appropriately to minimise risks during O&M tasks

- Minimise project downtime to reach and maintain targeted availability

- Support both income generation and cost management

O&M scour monitoring

Scour should also be monitored and assessed during the O&M phase. Scour-related tasks should be conducted around unprotected foundations, jacked-up installation vessels and vessels with legs on the seabed. DHI Scour Calculator and Computational Fluid Dynamics (CFD) can help determine the mitigations activities to pursue.

Phase 5: Decommissioning

Decommissioning processes are like the installation processes, but in reverse. Decommissioning requirements are unique to each project site depending on structure type, equipment, natural conditions, regional regulations and more.

Tools like the cloud-based MOOD Decom can provide high-quality metocean information to support decommissioning activities like:

- Quantifying uncertainties

- Integrating probabilistic measures of workability

- Monitoring near-real-time environmental impacts

- Forecasting and hindcasting

Accurate metocean information and translation into practical risk measures are the keys to developing reliable workability assessment that ensure cost-efficiency and provide safer, compliant operations.

Managing offshore wind development challenges

The global offshore wind industry is showing no signs of stopping in the coming decades. Overcoming engineering and environmental challenges in offshore wind farm development phases can be complicated, but it doesn’t have to be. As read above, there are plenty of specialty tools and expertise available to get you started.

While cost and scalability are key considerations for a project’s success, it’s also vital to consider other sustainability factors in each phase of an offshore wind farm development. Each renewable energy project should map out how it can align with and support the UN’s Sustainable Development Goals.